Major Garment Manufacturing Zones in Bangladesh

Alitra presence

- Bangladesh

- Cambodia

- China

- Egypt

- Hong Kong

- India | Bangalore

- India | Chennai

- India | Gurgaon

- India | Triupur

- Indonesia

- Myanmar

- Pakistan

- Spain

- Sri Lanka

- Turkey

- Vietnam | Hanoi

- Vietnam | HCMC

Overview of Bangladesh's Garment Manufacturing Industry

-

1. Export Volume

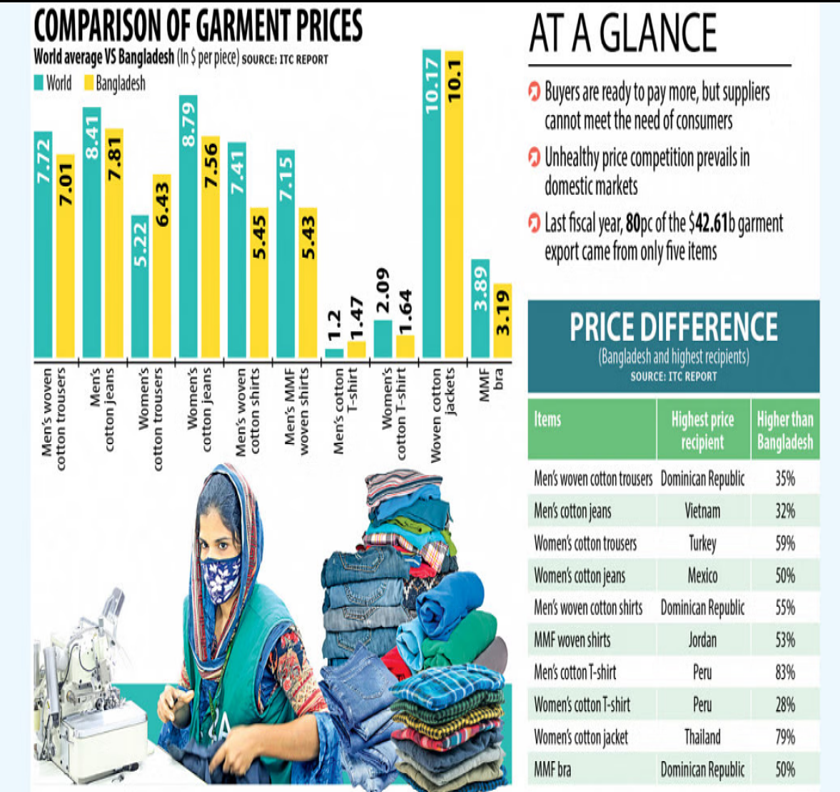

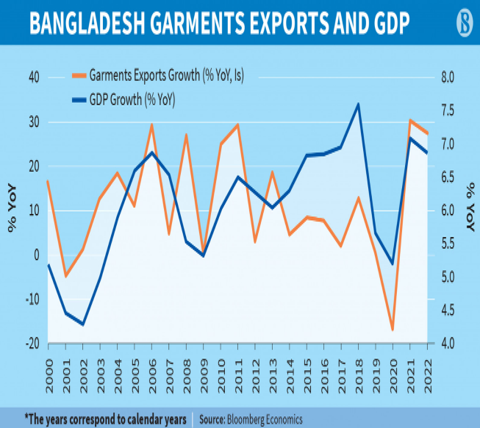

In 2023, Bangladesh's Ready-Made Garment (RMG) sector achieved record export earnings of $47.38 billion, comprising $25.73 billion from knitwear and $21.25 billion from woven garments. RMG Bangladesh

-

1. Export Volume

In 2023, Bangladesh's Ready-Made Garment (RMG) sector achieved record export earnings of $47.38 billion, comprising $25.73 billion from knitwear and $21.25 billion from woven garments. RMG Bangladesh

-

2. Contribution to GDP

The RMG sector contributes approximately 10.35% to Bangladesh's GDP. BB

-

3. Workforce Size

The garment industry employs over 5 million workers, with women constituting more than 55% of the workforce. Textile Focus

-

4. Global Standing

The garment industry employs over 5 million workers, with women constituting more than 55% of the workforce. Textile FocusBangladesh is the world's second-largest garment exporter after China. SlideServe+2United Nations University+2ResearchGate+2

-

5. Industry Highlights

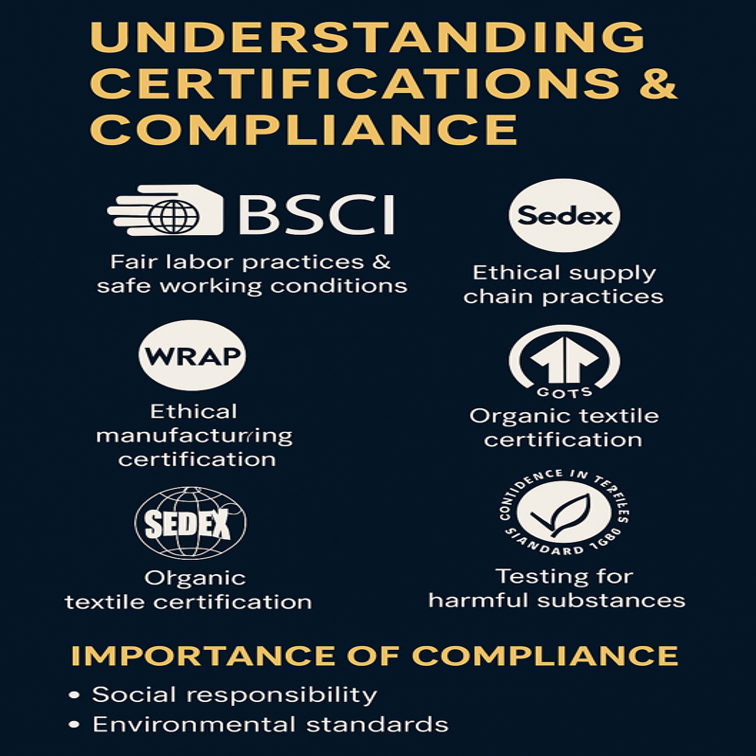

Sustainability and Compliance: Bangladesh hosts numerous eco-friendly factories certified by international standards, emphasizing sustainable and ethical manufacturing practices.

Skilled Workforce: The sector benefits from a large, skilled, and cost-effective labor force, contributing to its competitive advantage.

Infrastructure Development: Continuous improvements in infrastructure and logistics have enhanced the efficiency of the supply chain.

Why Partner with Bangladeshi Garment Factories?

Cost-Effectiveness

Benefit from some of the world’s most competitive production costs without sacrificing quality—thanks to a highly efficient, large-scale workforce and affordable infrastructure

Large-Scale Production Capacity

Home to thousands of export-ready factories, Bangladesh can meet high-volume orders with consistent lead times and global delivery capabilities.

Wide Range of Product Offerings

From basic tees to complex fashionwear, denim to outerwear—Bangladeshi manufacturers cater to diverse market needs across all segments

Case Studies / Success Stories

Case Study 1: Fast Turnaround for a Fashion Retailer

A European fast fashion retailer faced delays with previous suppliers. We on boarded a Dhaka-based factory capable of delivering 30,000 pcs within 25 days—resulting in a 25% faster turnaround and 10% cost savings.

Case Study 2: Sustainable Sourcing for an Eco-Conscious Brand

We helped an Australian startup identify a GOTS and OEKO-TEX certified knitwear supplier. Within 3 months, they launched their organic kidswear line with full traceability and RSL compliance.

Case Study 3: MOQs Aligned with Growth Goals

A North American brand entering the South Asian market needed flexible MOQs. We aligned them with a mid-sized, compliant unit allowing scalable growth without overstock risks.